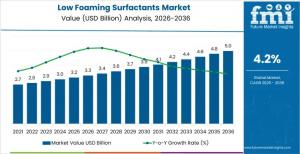

Global Low Foaming Surfactants Market Projected to Reach USD 5.0 Billion by 2036 Driven by Industrial Automation

The low foaming surfactants market is projected to grow from USD 3.3 billion in 2026 to USD 5.0 billion by 2036, at a CAGR of 4.2%.

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- The global low foaming surfactants market is entering a decade of steady, efficiency-driven expansion, with its valuation projected to rise from USD 3.3 billion in 2026 to USD 5.0 billion by 2036. This growth, representing a compound annual growth rate (CAGR) of 4.20%, is fundamentally shaped by the industrial sector’s transition toward automated, closed-loop cleaning systems where foam control is the primary determinant of operational uptime and throughput.

Unlike high-growth commodity markets, the low foaming surfactants sector is characterized by technical precision and high switching costs. In high-speed industrial environments, excess foam can disrupt sensors, cause pump cavitation, and necessitate costly downtime. Consequently, market performance is increasingly tied to process reliability rather than discretionary demand, as global manufacturers in the food, beverage, and pharmaceutical sectors seek to optimize their Clean-in-Place (CIP) and Clean-out-of-Place (COP) protocols.

Strategic Market Dynamics: Reliability Over Hype

The integration of low foaming surfactants is a critical factor for facilities aiming to reduce water consumption and energy use. By minimizing foam generation during high-agitation processes, these specialized chemicals allow for faster rinse cycles and more consistent cleaning results.

• Process Stability: Buyers are exhibiting moderate risk aversion, favoring proven formulations that maintain predictable behavior across varying temperature, pH, and water-hardness conditions.

• Chemistry Dominance: Nonionic EO or PO Block Surfactants lead the market with a 44% share. These chemistries are preferred for their superior detergency and cloud-point tuning, which ensures foam suppression even under extreme pressure and heat.

• Application Intensity: Industrial and Institutional (I&I) cleaning accounts for 34% of demand. High cleaning frequencies in healthcare facilities, warehouses, and commercial kitchens drive consistent, recurring volume.

Request For Sample Report | Customize Report | Purchase Full Report -

https://www.futuremarketinsights.com/reports/sample/rep-gb-31474

Regional Growth Insights: Asia Pacific and Brazil Lead the Curve

The demand for low-foam technology is expanding most rapidly in regions undergoing significant industrial modernization.

• China (5.4% CAGR): As the world’s manufacturing hub, China is leading the market through the large-scale adoption of automated bottle washing and industrial surface cleaning. Local producers are scaling cost-effective nonionic solutions to meet the needs of a maturing food and beverage infrastructure.

• Brazil (5.0% CAGR): Driven by its robust agro-industrial and textile sectors, Brazil is seeing a steady shift toward low-foam formulations in dairy processing and textile finishing units, where humidity and temperature variables demand stable chemical performance.

• United States (3.9% CAGR): The U.S. market is defined by performance-driven adoption. Growth is anchored by strict hygiene protocols in healthcare and the presence of global detergent giants focusing on high-efficiency, concentrated formulations.

• Germany (3.8% CAGR): Known for precision engineering, Germany’s market is fueled by automotive metal cleaning and closed-loop industrial maintenance, where low residue and high reproducibility are non-negotiable.

• South Korea (3.4% CAGR): Demand is concentrated in the electronics and precision manufacturing sectors, where foam interference can compromise the quality of high-value components.

Competitive Landscape: The Shift from Scale to Know-How

In the current market, supplier leverage is derived from formulation expertise and application support rather than production scale alone. Leading players are moving away from commodity blends toward engineered surfactant architectures that offer measurable gains in throughput.

Key industry participants include:

• BASF SE and Dow Chemical Company, who lead with versatile, high-shear stable formulations.

• Evonik Industries AG and Clariant AG, focusing on hard-surface and industrial applications with optimized rinse-off profiles.

• Solvay SA and Croda International Plc, who are differentiating through biodegradable, low-environmental-impact options that meet tightening global eco-label standards.

• Stepan Company, Nouryon, Huntsman Corporation, and Kao Corporation, providing specialized support for agricultural adjuvants, oilfield chemicals, and institutional maintenance.

Technical and Regulatory Challenges

Achieving a balance between foam suppression and functional performance remains a technical hurdle. Some low-foaming agents can have limited wetting or emulsification properties compared to their high-foam counterparts, requiring sophisticated formulation expertise. Furthermore, evolving regulatory frameworks—such as the transition away from APEO-containing substances—are narrowing the selection of raw materials, increasing development costs for smaller manufacturers.

Future Outlook: Sustainability and "Smart" Cleaning

By 2030, the market is expected to see a surge in bio-based, sugar-derived backbones as companies work to improve their Scope 3 emissions profiles. The rise of "Smart" cleaning—incorporating IoT-enabled sensors for real-time concentration monitoring—will further solidify the role of low foaming surfactants as essential components in the data-driven factory of the future.

Similar Industry Reports

Low-Foaming Detergent Market

https://www.futuremarketinsights.com/reports/low-foaming-detergent-market

Low-VOC Industrial Primers Market

https://www.futuremarketinsights.com/reports/low-voc-industrial-primers-market

Low-Cobalt Precursors Market

https://www.futuremarketinsights.com/reports/low-cobalt-precursors-market

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.